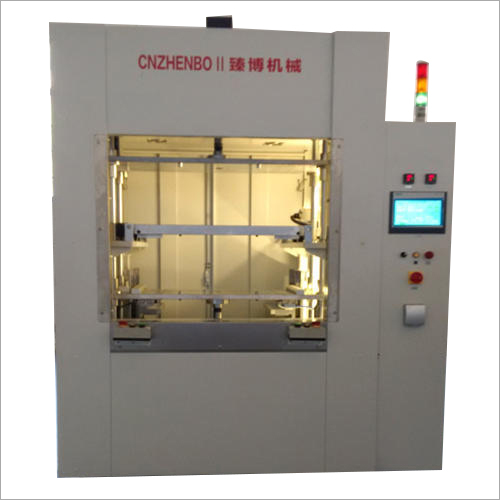

Infra Red Plastic Welder

Product Details:

- Automation Automatic

- Frequency 50 Hertz (HZ)

- Type 3 Phase

- Material Stainless Steel

- Product Type Infra Red Plastic Welder

- Voltage 220 Volt (v)

- Click to View more

Infra Red Plastic Welder Price And Quantity

- 1400000 INR/Unit

- 1 Unit

Infra Red Plastic Welder Product Specifications

- Automatic

- 220 Volt (v)

- Infra Red Plastic Welder

- 3 Phase

- Stainless Steel

- 50 Hertz (HZ)

Infra Red Plastic Welder Trade Information

- Cash Advance (CA)

- 7 Days

- All India

Product Description

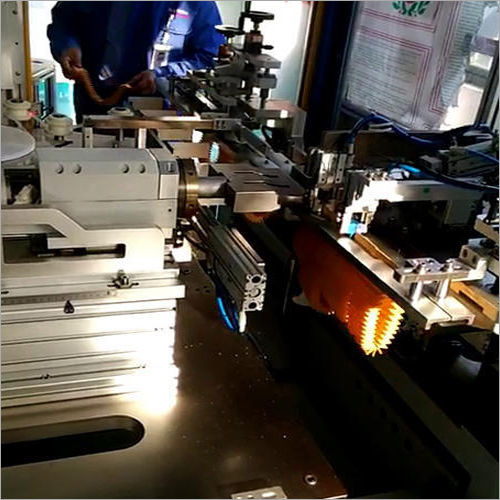

Infra Red Plastic Welder that presented by us is engineered to be utilized for joining of plastics parts as well as for repairing cracks. Suitable of automotive part, PA66, intricate profile, GF material, ABS, PC, etc., the advantages of machine are strong joint, non-sticky, no cleaning required, and high dimensional accuracy. Made up of graded stainless steel materials with developed technologies, Infra Red Plastic Welder features 220V voltage, electric power source, 3 phase, speed of 1200 Pcs/Hr, and frequency of 50 Hz.

Product details

|

Packaging |

Wooden Box |

|

voltage |

220 V |

|

Usage/Application |

Joining Of Plastics Pieces And Also To Repair Cracks. |

|

Frequency |

50 Hz |

|

Speed |

1200 Pcs/Hr |

|

Power Source |

Electric |

|

Phase |

3 Phase |

|

Material |

Stainless Steel |

|

Brand |

MP Sonic |

Advanced Automation for Seamless Plastic Welding

This Infra Red Plastic Welder utilizes state-of-the-art automation, significantly minimizing manual intervention and reducing error rates. With its 3-phase operation and infrared technology, users can expect consistent, high-quality welds even in demanding industrial settings. The automated process enhances productivity, supporting large-scale manufacturing and fabrication needs.

Durable Stainless Steel Construction for Longevity

Built using premium stainless steel, the welder resists corrosion and physical wear, ensuring exceptional durability. Its sturdy build is tailored to withstand regular usage in busy workshop environments. Whether you are a fabricator, trader, or manufacturer, this machine offers long-term reliability alongside superior welding performance.

FAQ's of Infra Red Plastic Welder:

Q: How does the Infra Red Plastic Welder operate?

A: The Infra Red Plastic Welder uses infrared radiation to heat and join plastic parts. It operates automatically with 3-phase power at 220 Volts and 50 Hertz frequency, allowing for efficient and consistent welding with minimal manual intervention.Q: What types of industries can benefit from using this welder?

A: Industries engaged in manufacturing, fabrication, and assembly of plastic components-such as automotive, packaging, and consumer goods-will especially benefit from this reliable and robust welding solution.Q: When is it ideal to use an automatic Infra Red Plastic Welder?

A: This welder is best used when high-throughput and precision are required. It is ideal for continuous production environments where quality control and automation can greatly enhance productivity and consistency.Q: Where can I purchase or source the Infra Red Plastic Welder in India?

A: You can source this welding machine directly from exporters, manufacturers, suppliers, and retailers based in India, who cater to both domestic and international markets.Q: What is the process involved in infrared plastic welding with this equipment?

A: The welding process involves directing controlled infrared heat onto the surfaces of plastic components, causing them to melt and form a strong, seamless joint upon cooling-all managed automatically by the machine.Q: How is this machine advantageous compared to traditional plastic joining methods?

A: The primary advantage lies in automation and precision, leading to improved speed, reduced labor costs, and superior weld quality. Its stainless steel construction also ensures long-term performance under heavy-duty use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Plastic Welder' category

Offices and Branches:

- Pune

- Delhi

- Bangalore

- Chennai

For sales & service please contact:

- Pune: 9821184360/07776966826

- Email: info.rlp@rtlravira.com / Jayprakash@rtlravira.com

- Delhi : 09810559745

- Email: deepakdk@rtlravira.com

- Bangalore: 9980549975

- Chennai : 8484910461