Ultrasonic Hand Gun Spot Welder

Product Details:

- Automation Manual

- Usage Spot Welding , Reveting , Staking On Plastic Parts

- Type Single Phase

- Product Type Gun Spot Welder

- Voltage 220 Volt (v)

- Click to View more

Ultrasonic Hand Gun Spot Welder Price And Quantity

- 1 Unit

- 120000 INR/Unit

Ultrasonic Hand Gun Spot Welder Product Specifications

- Spot Welding , Reveting , Staking On Plastic Parts

- 220 Volt (v)

- Gun Spot Welder

- Manual

- Single Phase

Ultrasonic Hand Gun Spot Welder Trade Information

- Cash Advance (CA)

- 7 Days

- All India

Product Description

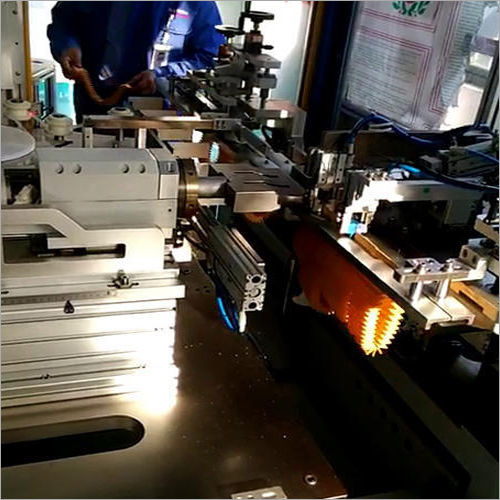

Ultrasonic Hand Gun Spot Welder we put forward is suitable for spot welding, staking on plastic parts, and reverting. This kind of welding equipment is engineered for accurate laser engraving with less operating time. Featured with small size, noiseless operation, space saving, and easy operation, it is made of rust proof stainless steel parts, powder coated metal housing and other contact electric components. In addition to this, Ultrasonic Hand Gun Spot Welder is available in different models at compromising prices.

Product Details:

|

Material |

All kind of thermo plastics, blisters pkg |

|

Rated Input Power(KVA) |

500/800/1200 W/ 28Khz / 35Khz |

|

Model Name/Number |

RWS |

|

Automation Grade |

Manual |

|

Voltage |

220V |

|

Phase |

Single Phase |

|

Frequency |

50 Hz |

|

Surface Treatment |

NA |

|

Rated Capacity |

700-900 piece/h |

Efficient and Precise Plastic Welding

This ultrasonic spot welder leverages high-frequency sound waves to join plastic parts efficiently. The manual operation ensures hands-on precision, while automation streamlines workflows and boosts productivity. Its ability to perform spot welding, riveting, and staking increases its application across industries reliant on plastic manufacturing, from automotive to electronics.

Flexible Integration for Industrial Use

Designed for single-phase 220 Volt operations, the welder integrates seamlessly into Indian manufacturing environments. Its role suits exporters, fabricators, importers, or retailers seeking superior bonding in plastic assemblies. Reliability and adaptability make it a valuable asset for both large-scale and niche production facilities.

FAQ's of Ultrasonic Hand Gun Spot Welder:

Q: How does the Ultrasonic Hand Gun Spot Welder operate?

A: This spot welder uses ultrasonic vibrations to create localized heat, which melts and fuses plastic components together. It is manually operated but features automation to facilitate repetitive tasks, ensuring accuracy and efficiency during spot welding, riveting, or staking operations on plastic parts.Q: What types of plastic components can be welded with this device?

A: The welder is suitable for a wide variety of thermoplastic materials commonly used in industries such as automotive, electronics, packaging, and consumer goods. It is ideal for joining, shaping, or attaching plastic parts that require precision and durability.Q: When should I use the spot welder for riveting or staking instead of traditional methods?

A: Riveting or staking with an ultrasonic spot welder should be chosen when you require a clean, strong, and rapid joint without introducing external fasteners. This method reduces cycle times and enhances the overall finish compared to traditional mechanical joining methods.Q: Where is this welder most commonly used in India?

A: The Ultrasonic Hand Gun Spot Welder is widely utilized across India in manufacturing plants, assembly workshops, and fabrication units that process plastic components. Its adaptability makes it valuable for both centralized factories and smaller production shops.Q: What is the standard process for spot welding with this equipment?

A: Begin by aligning the plastic parts and placing the welding tip at the targeted joint. When activated, the ultrasonic energy precisely melts the material at that spot, forming a strong bond upon cooling. The process is quick, consistent, and can be automated for repetitive tasks.Q: How does the operator benefit from the automation features?

A: Automation in the spot welder reduces manual fatigue, ensures consistent weld quality, and minimizes human error. This leads to increased throughput, reduced downtime, and reliable product output, making it especially beneficial in high-volume production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Plastic Welder' category

Offices and Branches:

- Pune

- Delhi

- Bangalore

- Chennai

For sales & service please contact:

- Pune: 9821184360/07776966826

- Email: info.rlp@rtlravira.com / Jayprakash@rtlravira.com

- Delhi : 09810559745

- Email: deepakdk@rtlravira.com

- Bangalore: 9980549975

- Chennai : 8484910461