Ultrasonic Spot Welder

20000.00 - 50000.00 INR/Unit

Product Details:

- Function Joining thermoplastics and thin metals

- Voltage 220V AC Volt (v)

- Condition New

- Input Current 7A Max

- Cooling Method Air cooling

- Usage Plastic and metal spot welding

- Power 1500W Watt (w)

- Click to View more

X

Ultrasonic Spot Welder Price And Quantity

- 1 Unit

- 20000.00 - 50000.00 INR/Unit

Ultrasonic Spot Welder Product Specifications

- Plastic and metal spot welding

- Air cooling

- 1500W Watt (w)

- 7A Max

- New

- 220V AC Volt (v)

- Joining thermoplastics and thin metals

- 95% (conversion efficiency)

- 15 kg Kilograms (kg)

- F

- 0.5 - 10 mm Square Millimeter (mm2)

- 420 x 250 x 200 mm Millimeter (mm)

- Electric (solenoid actuator)

- Aluminum alloy housing with steel horn

- 20 kHz Kilohertz ( KHZ )

- Ultrasonic Spot Welder

- Adjustable, up to 250 Hz Hertz (HZ)

Ultrasonic Spot Welder Trade Information

- 1 Unit Per Month

- 7 Days

Product Description

Backed by rich experience in the respective field, and dedicated professionals, we have been able to bring forth the best quality Ultrasonic Spot Welder. Made of hi-tech components & parts and powder coated metal structure with developed technology, the machine has accurate dimension, ergonomic design and ideal weight for which effortless to transport and install at require point in production unit. Plus, Ultrasonic Spot Welder is checked perfectly by dexterous quality controllers to ensure its high efficiency, high production, hassle performance and low maintenance need.

Product Details:

| Material | MS Body |

| Type | Analog And HMI Controller |

| Rated Input Power | 500 Zw |

| Usage/Application | Spot Welding |

| Brand | Ravira |

| Phase | Single Phase |

| Frequency | 50 Hz |

| Surface Treatment | Polished |

| Rated Capacity | 50 Piece/h |

| Packaging | Carton Box |

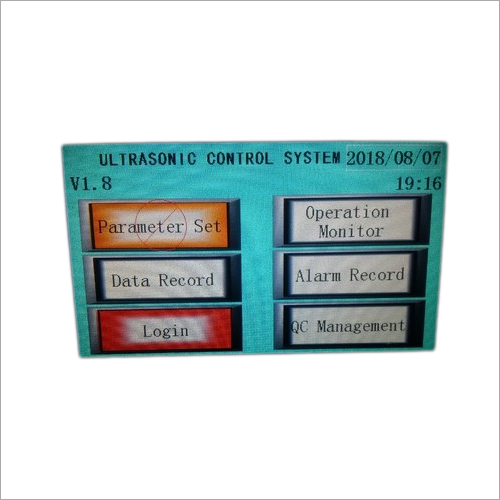

Advanced Digital Control for Precision Welding

The built-in digital microprocessor controller allows users to precisely adjust parameters such as cycle time, pulse frequency, and acoustic power directly via the control panel. This ensures consistent and repeatable spot welds, making the machine highly suitable for production environments where accuracy and efficiency are paramount.

Versatile Applications Across Multiple Industries

Engineered to serve a broad spectrum of applications, this ultrasonic spot welder is ideal for automotive, electronics, medical, and packaging sectors. Its adaptability to welding both plastics and metals with a welding area capacity from 0.5 to 10 mm2 makes it an essential addition to any manufacturing or assembly line.

Reliable and Safe Operation

Safety is fundamental in the design, featuring overload and overheat protection systems. The sturdy aluminum alloy body combined with air cooling enhances device longevity, while the LED status display offers real-time operational insights. The low noise output further promotes a safer and more comfortable workplace.

FAQ's of Ultrasonic Spot Welder:

Q: How does the Ultrasonic Spot Welder join thermoplastics and metals?

A: The Ultrasonic Spot Welder uses high-frequency ultrasonic vibrations generated by a solenoid actuator to create localized heat at the welding interface. This process melts the materials, allowing them to bond securely without additional adhesives or fasteners.Q: What benefits does the digital microprocessor controller provide?

A: The digital microprocessor controller enables precise adjustment of welding parameters such as cycle time, power output, and pulse frequency. This ensures high efficiency, repeatability, and optimal weld quality across various applications.Q: When should you choose manual versus semi-automatic operation modes?

A: Manual mode is ideal for low-volume or custom welding tasks, allowing for greater operator control. Semi-automatic mode is preferred in high-volume production lines for faster, consistent weld cycles and reduced operator fatigue.Q: Where can this ultrasonic spot welder be used?

A: It is suitable for use in automotive, electronics, medical device manufacturing, and packaging industries, wherever precise joining of plastics and thin metals is required.Q: What is the typical process for using this spot welder?

A: Users set the desired parameters using the control panel, place the materials between the horn and anvil, and initiate the weld via manual or semi-automatic mode. The welding cycle is completed in 0.1 to 3 seconds, with status indicated on the LED display.Q: How is workpiece safety ensured during welding?

A: The machine features built-in overload and overheat protection systems, along with safe electrical insulation (Grade F) and air cooling, ensuring both operator and equipment safety during operation.Q: What advantages does the titanium welding horn offer?

A: The titanium welding horn provides excellent durability, high acoustic efficiency, and superior resistance to wear and fatigue, contributing to long-term, reliable performance in demanding applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Vibration Welder' category

Offices and Branches:

- Pune

- Delhi

- Bangalore

- Chennai

For sales & service please contact:

- Pune: 9821184360/07776966826

- Email: info.rlp@rtlravira.com / Jayprakash@rtlravira.com

- Delhi : 09810559745

- Email: deepakdk@rtlravira.com

- Bangalore: 9980549975

- Chennai : 8484910461

Back to top